Our Process

How We Work Together

Click on each step to explore our proven process for taking your product from concept to manufacturing.

Discovery

Industrial Design

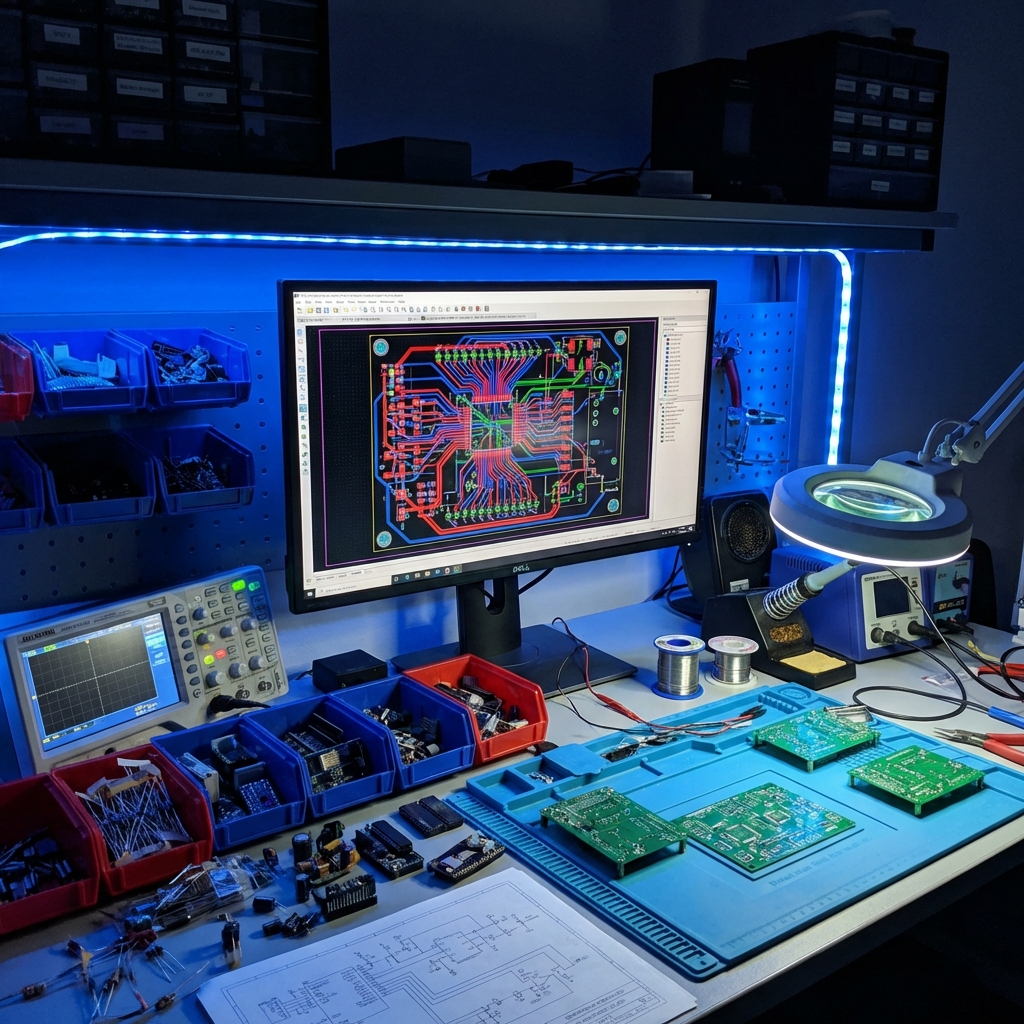

PCB Design

Prototyping

Validation

DFM

Step 01

Discovery Meeting

It starts with a conversation. We schedule a one-on-one meeting to deeply understand your product vision, target market, technical requirements, and business goals. This foundation ensures we're aligned from day one.

- → Understand your product vision

- → Define technical requirements

- → Identify target market & users

- → Create project roadmap